THE THERMOLOGICA - CONCEPT IS A HOUSE BASED ON A STEEL PLATE CONSTRUCTION PROVIDING AN INDOOR CLIMATE THAT FULFILS ALL TODAY'S DEMANDS.

A HOUSE WITH GREAT VISIONS.

The steel plates, which are the essential part of the construction, act

simultaneously as climate screen and supporting structure.

The principle is characterized by the full control of the ventilation and no diffusion through the outer walls, which results in an optimal indoor climate.

The outer walls for a one-storied residence consist of a 12/13 mm steel plate and 400 mm insulation (Danish climatic conditions). The steel plates are provided with cathodic protection, which eliminates corrosion. The sacrificial anodes are, for instance, made of magnetite and have a durability of 200 years or more. With such sacrificial anodes mounted (and replaced every 200 years) the steel plates are in fact everlasting.

The ThermoLogica house functions as a Faraday's Cage. The roof structure should therefore include thin steel plates, which apart from acting as a conventional wind bracing, also serves the purpose of rejecting cosmic radiation from space.

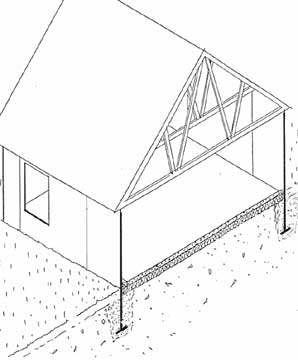

Placing the steel plates

The steel plates are founded 1.25 - 1.50 m below surface level. The steel plates are placed in an excavated ditch following the contour of the house. A tractor crane lifts the plates and places them for temporary buttressing.

There is no concrete in the foundation!

A cross plate is provided below the steel plates instead of a foundation. The steel plates are guided at the top by a U-profile welded on one of the steel plates. The excavated soil is replaced and compacted.

The building is considerably lighter than traditionally built houses so the foundation pressure is reduced to 30-40%.

The

plates are placed with a distance of 3 mm dependent on the width of the

plates to allow for thermal expansion. The spacing between the plates

is filled with a visco-plastic seal, which is covered on the inside as

well as on the outside by a bituminous coating.

For a one family house, the placing of the steel plates can be finished in 2-3 days by two skilled laborers and a tractor crane (app. 25 running meters per day). The roofing is placed immediately afterwards, and the house is internally no longer exposed to weather conditions.

Drainage is not required. As a matter of fact the moistured soil is an advantage for the cathodic protection.

One

of most buildings weak points is the transition between the foundation

and the outer wall. Moisture and coldness have access through the joint.

With a steel plate going from well below the terrain to the roof this

difficulty is easily solved. Neither moisture nor thermal bridge is developed.

A three story building constructed in Ballerup, Denmark,

Two/three-storied buildings

Longer

steel plates demand a stronger section, which is made by increasing the

thickness of the plates to 18/22 mm. This greater thickness also provides

a potential for a greater energy transport up through the plates.

Basement

Due to the steel plate construction, it has again become possible to construct basements at a reasonable price: The steel plates are lengthened downwards, proportional to the depth of the basement.

Weekend cottages

The house in Espergærde was unoccupied during the months of October, November and December 1995, which meant a minimum supply of energy to the house (i.e. 80 kWh per month from ex. refrigerator and freezer). Temperature readings inside the house were, however, - in spite of many low outside temperature readings in November and a cold December, never lower than 13 oC.

A weekend cottage constructed according to the ThermoLogica principle have the advantage that the temperature inside the house never falls below zero, which means the risk of having frozen water pipes does not exist.

Injection of insulation material

The walls and the ceiling are filled with insulating materials in measurements required according to local

winter temperatures - in Denmark: 400 mm in the outer walls and 600 mm

above the ceiling.

No

gap is allowed between the wall insulation and the insulation of the ceiling.

The insulation in the walls will

settle with time - a few centimetres due to vibrations from traffic for

instance, and the insulation from the ceiling shall be allowed to follow.

A vapour barrier is mounted on the inside of the outer walls and below the ceiling. Measurements made in the existing experimental house show that after three years, no humidity (condensation) is found in these walls.

Air exchange due to the heat exchanger

An analysis of the amount of air required to cover a human being's need for oxygen and remove the humidity of the expiration was made in co-operation with Rigshospitalet (the State University Hospital in Copenhagen), Byggecentrum's Energikontor (the Danish Centre for Structure and Energy) and experts working with Eskimo "Igloo-huts". The analysis formed the basis for the forced air exchange, which is regulated by the heat exchanger ventilators.

The oxygen requirement and the removal of the humidity from the expiration were then transformed into m³ air. For an average human being the amount of air is between 8 and 9 m³ per hour, the removal of the humidity being the determining factor.

The required air volume depends on the number of people in the house. A large number of people demands more ventilation, which in turn provides more "free heating".

The system has been tested during four winters - in accordance with the stated amounts of air - and with great success.

Windows

The window area in the experimental house corresponds to 10% of the floor area of the house. Light disperses extremely well and the house appears open and sunny. Experience proves that with the new type of glasses in the windows the area could, if so desired,

easily be increased to 20 - 30% without affecting the indoor temperature

level.

Windows facing directly south will always provide a positive energy flow, even during the winter.

Firewall construction

Fire protection constructions are generally used in semi-detached housing between the accommodation units. Such construction shall pass through the roof.

This, however, is not necessary using the principles of ThermoLogica in houses that are insulated over the ceiling, as the insulation is considered fireproof, when placed on a stable support.

This means that:

-

the

ordinary fire wall above the ceiling can be avoided;

- as

the dead weight of this wall does not occur, the partition between the

residences can be constructed as light walls; and

- as a consequence hereof, the fire wall being light, the required foundation below the fire wall is no longer needed, and the structure can be made cheaper.

This means reduced building costs.

Outer covering

Traditionally built houses in Denmark are either built of bricks or wood. To maintain this appearance a thin brick wall can cover the steel plates. The bricks are supported on a L-profile, welded to the steel plates at normal foundation level. The cover is fixed to the steel walls by light steel fixations spot-welded to the steel plates.

Architecture

By using this principle, the architect has many more possibilities to create and develop his ideas to shape the house. The supports can be welded onto the plates and create non-traditional forms which are not confined to horizontal or vertical lines. Three-dimensional effects may also be added.

The steel plates can, as mentioned above, be covered by materials such as brick, wood, profiled steel plates, turf, laminates or clinkers.

Aluminium may be used cautiously. If aluminium has direct contact with the steel, the aluminium plates will corrode due to the galvanic effect between steel and aluminium. Neoprene, wood or similar materials should be used to guard a distance between the two metals.

Ordinary air change

The fire regulations prescribe at least one hinged window in each room. In case of an electrical failure or other failure that might interfere with the ventilation it is always possible to open a window to get fresh air; the time needed to reheat the rooms, however, is longer than usual as there is no direct heating of the rooms.

Special conditions:

Earthquake resistance

In earthquake zones, the ThermoLogica concept offers many advantages. The construction is very light. The house weighs much less than a brick house or a concrete house with foundations. The structure is very flexible diminishing the transmission of earthquakes through the building.

Soft grounds

In marsh areas such as large parts of the Netherlands, it is often necessary to use a pile foundation with piles of up to 30 m.

ThermoLogica is a very lightweight construction. The weight of the steel plates in a 120 m2 house is about 18 t. In a similar, traditional house, concrete and bricks will weigh 70-80 t.

Patent

Patent

has been taken out in most industrial countries in the temperate zone.